If you’re considering creating custom silicone products, whether it’s for baby items, kitchenware, toys, or industrial components, you’re likely wondering: How much does it cost to make a custom silicone mold? At Wolife, we specialize in providing tailored OEM silicone mold solutions, helping you bring your vision to life with precision and quality.

In this blog, we break down the factors that affect the cost of custom silicone molds, so you can make informed decisions for your next project.

Understanding the Basics of Silicone Molding

Custom silicone molding involves creating a mold based on your product design. Once the mold is made, it can produce large quantities of silicone parts quickly and efficiently. The mold itself is a key investment, as its quality determines the precision, durability, and final look of the product.

At Wolife, we use advanced techniques to create high-quality silicone molds that deliver:

-

Precision in design

-

Long-lasting durability

-

Cost-efficiency in production

But how is the cost determined? Let’s take a closer look.

Factors That Affect the Cost of a Custom Silicone Mold

Several elements influence the cost of making a custom silicone mold. Here are the key factors:

1. Product Complexity

The design of the product plays a major role in mold costs. Simple designs with basic shapes are less expensive, while complex designs with intricate details or multiple components require more advanced mold-making techniques.

-

Simple designs: Lower cost (e.g., basic silicone trays or teething rings).

-

Complex designs: Higher cost (e.g., products with detailed textures, interlocking parts, or multi-color features).

2. Mold Material

The material used to make the mold can vary depending on your production needs:

-

Aluminum molds: Cost-effective for small to medium production runs.

-

Steel molds: More expensive upfront but highly durable for large-scale production.

At Wolife, we work with you to choose the right mold material that balances cost and durability.

3. Mold Size

The size of the mold impacts the cost as it determines the amount of material and machining required. Larger molds require more resources, increasing the overall price.

4. Production Volume

The intended production volume influences mold design. If you’re planning for:

-

Small production runs: A simpler mold will suffice, keeping costs lower.

-

High-volume production: Durable, high-precision molds are necessary, which increases costs upfront but pays off over time.

5. Customization and Special Features

If your product requires additional features like logos, textures, or multi-part molds, this adds to the complexity and overall cost. Customized branding or intricate patterns demand more detailed mold engineering.

6. Design and Prototyping Costs

Before the mold is made, the product design and prototyping phase are critical. Costs include:

-

3D product design

-

Prototype samples

-

Design modifications

At Wolife, we offer comprehensive design and prototyping services to ensure the final mold perfectly matches your product vision.

Average Cost of Custom Silicone Molds

While costs can vary depending on the factors listed above, here’s a general estimate for custom silicone mold pricing:

-

Basic molds: $500 - $2,000 (simple designs with minimal details)

-

Intermediate molds: $2,000 - $5,000 (medium complexity, larger sizes)

-

Advanced molds: $5,000 - $15,000+ (highly complex designs, multi-part molds, and detailed finishes)

Keep in mind that these are rough estimates. For an accurate quote, it’s essential to consult with our experts based on your specific requirements.

Why Choose Wolife for Custom Silicone Mold Solutions?

At Wolife, we specialize in OEM silicone mold production, providing full-scale services from design to delivery. Here’s what sets us apart:

-

Expert Engineering: Our team has years of experience in creating precise, high-quality molds tailored to your needs.

-

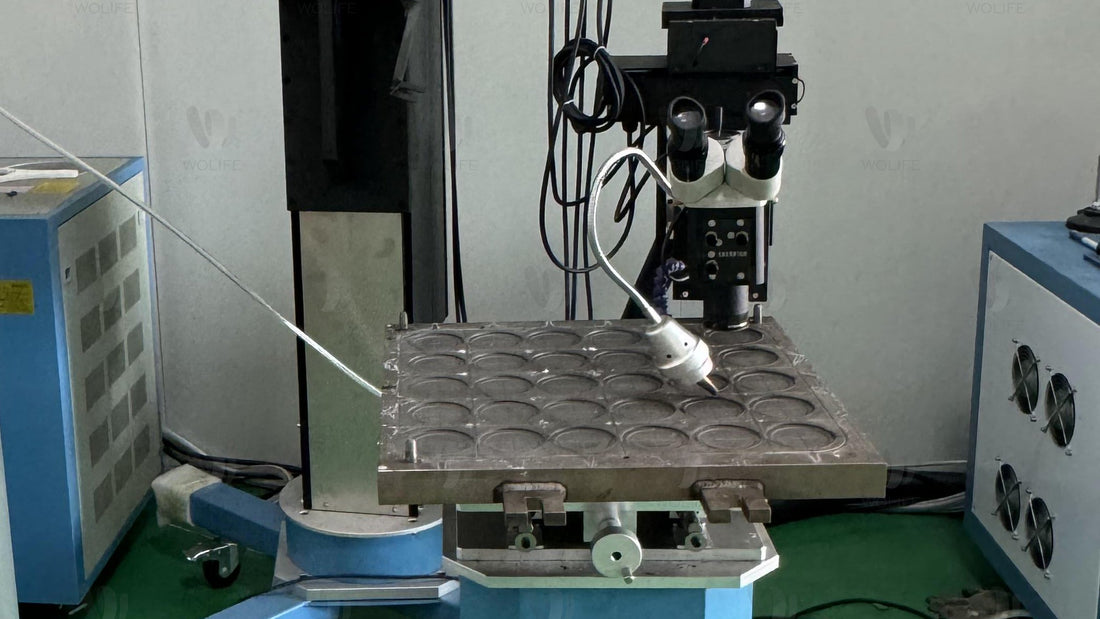

Advanced Technology: We use state-of-the-art machinery for efficient and accurate mold production.

-

Cost-Effective Solutions: We work with you to optimize costs without compromising quality.

-

End-to-End Support: From initial design and prototyping to final production, we guide you every step of the way.

-

Global Experience: Trusted by businesses worldwide, we deliver molds that meet international quality standards.

Get a Quote for Your Custom Silicone Mold

If you’re ready to bring your silicone product to life, Wolife is here to help. Our team of experts will work closely with you to understand your needs, develop your design, and create a high-quality mold that fits your budget.

Contact us today for a free consultation and a detailed quote tailored to your project!

Let’s turn your ideas into reality.

About Author

We are dedicated to pushing the boundaries of possibility in silicone product manufacturing and our extensive range of inhouse designs and molds across baby, pet, homewares and more allows companies to customize and create products specific for their brand and market needs.

Whether you are looking for a company to bring your ideas and brand to life or looking for ready to go items with packaging and branding, WOLIFE is ready to help your business grow.

WOLIFE looks forward to collaborating with you!

Using LSR in Hearing Components

Using LSR in Hearing Components Why Silicone Cooking Utensils and Baking Trays Don’t Melt – The Science Explained

Why Silicone Cooking Utensils and Baking Trays Don’t Melt – The Science Explained 10 Creative Products You Didn’t Know Could Be Made with Silicone

10 Creative Products You Didn’t Know Could Be Made with Silicone Common Quality Control Challenges in Silicone Manufacturing

Common Quality Control Challenges in Silicone Manufacturing